Fiber Laser Sheet Cutting Machine

P Series

Capabilities

Enhanced Productivity

Experience a productivity boost like never before with the Bodor P Series fiber laser cutting machine. Say goodbye to tedious operations as automated cutting is just a click away, saving you valuable time and enhancing overall productivity. Streamline your workflow and supercharge your productivity with ease.

Sustainable Solutions for Resource Efficiency

We are committed to minimizing resource waste and reducing environmental impact. The P Series fiber laser cutting machine is designed with resource efficiency in mind, optimizing the use of materials, gases, and electricity. We ensure a sustainable approach to sheet metal cutting by reducing costs and maximizing value.

Unmatched Performance and Precision

The Bodor P Series fiber laser cutting machine represents the pinnacle of laser technology and performance. Meticulously crafted with advanced automation features and robust safety measures, it offers an unparalleled cutting experience.

Seamless Integration

We take pride in simplifying operations for our clients. With our one-second edge-finding technology, you can say goodbye to manually locating cutting positions. Plus, our intuitive touchscreen interface makes operating the machine a breeze and requires minimal training.

Safety First

Safety is our top priority. Our fiber laser cutting machines are equipped with visual collision detection and active collision avoidance functions. These features ensure potential collisions are detected and avoided, keeping you and your team safe. Additionally, our machines come with automatic cleaning and intelligent air pressure control that extends the lifespan of the equipment and reduces maintenance costs.

Unparalleled Cutting Quality

We are dedicated to delivering top-notch cutting quality every time. This means more accurate results, reduced waste, and happier customers. Our high-speed cutting processes enable faster cutting speeds, boosting production efficiency and output. With our fiber laser cutting machines, you can achieve a level of precision that exceeds expectations.

Features and Enhancements

One-second Edge Finding

Leveraging our innovative Space Eye technology, the Bodor P Series offers rapid material positioning and focus calibration. Through the use of an optical camera, this cutting-edge system automatically identifies the material’s position, locates its vertices, and determines angular offset within a mere three seconds.

Visual Collision Avoidance

With our highly intelligent visual collision avoidance technology, users can now benefit from multi-dimensional warnings tailored to different operating scenarios. The system provides the flexibility to choose between high or low-sensitivity modes, ensuring optimal operator safety.

Laser Head Active Obstacle Avoidance

The Bodor P Series prioritizes cutting process stability by implementing optimized tracking algorithms. By proactively identifying obstacles in advance, the system allows the motor to perform at its best. The system swiftly responds when an obstacle is detected, avoiding any potential disruption. This feature is particularly beneficial for addressing distortion in thin plate batch cutting, ensuring high-efficiency cutting results.

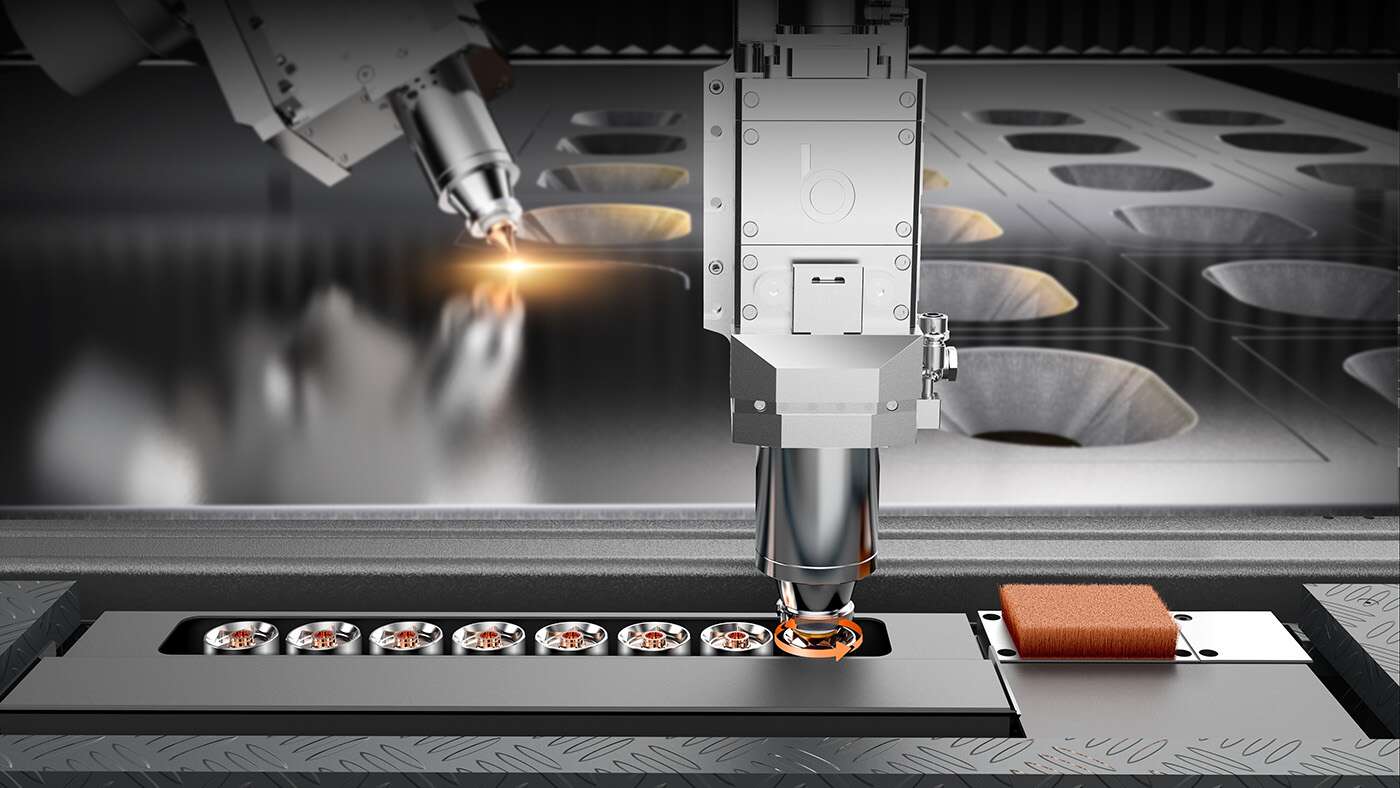

Automatic Nozzle Changer

The Bodor P Series introduces a remarkable feature known as the automatic nozzle changer, revolutionizing the cutting process. This innovative technology eliminates manual intervention when replacing nozzles, providing unparalleled convenience. Additionally, the machine incorporates automatic calibration and cleaning capabilities, significantly reducing repetitive manual labor and saving valuable time costs.

Bevel Cutting (Optional)

For those seeking precise angle cutting, the Bodor P Series offers an optional bevel-cutting function that supports various bevel shapes. This advanced feature allows for gapless assembly solutions, minimizing the need for fillers and simplifying the welding process.

Remnant Typesetting

The Bodor P Series incorporates a highly convenient remnant typesetting function, designed to simplify the nesting process. With just a smartphone photo, users can easily generate graphic output, making this integrated system incredibly user-friendly.

Compatible Nesting Software with Tekla

The nesting software for the Bodor P Series is highly compatible with Tekla software. It can automatically divide the overall drawing into individual parts and extract crucial part attributes such as material, thickness, and quantity. The software incorporates a multi-layer display feature that enhances the convenience of marking, outlining, and labeling. The intelligent matching function automatically selects optimal cutting parameters based on material information, resulting in efficient nesting and maximized sheet utilization.

P Series Full Function

Specifications and Parameters:

- P3

- P4

- P6

- P12

- Working area 3048mm*1524mm

- Laser output power 60000W / 40000W / 30000W / 24000W / 20000W / 12000W / 6000W / 3000W

- X/Y-axis positioning accuracy ±0.05mm/m

- X/Y-axis repositioning accuracy 0.02mm

- X/Y-axis max. linkage acceleration 4G

- X/Y-axis max. linkage speed 200m/min

Products

I-Series

P-Series

H-Series

Ready to Get Started

Reach out to us today to learn more about our P Series Plate Cutter!