Kodiak CNC & Oxy-Fuel Cutting Torch

Have a Question about Kodiak cnc machines?

Ask a Question- Hypertherm Edge Connect CNC

- CSI operator console

- Hypertherm plasma power supplies

- Hypertherm automatic torch height control

- CSI motorized oxy-fuel lifters

- Oxy-fuel torches from Harris, Victor, Oxweld, and more

- Bridge heat shields for thermal protection

- Bosch-Rexroth drive system

- Bosch-Rexroth linear ways and linear block bearings

- Automatic lubrication system (Less maintenance)

- Automatic rail cleaners (Less maintenance)

- Solid steel bridge machined for precision

- The Kodiak system is a high precision CNC Plasma and oxy-fuel cutting machine that features multiple plasma and oxy-fuel cutting stations.

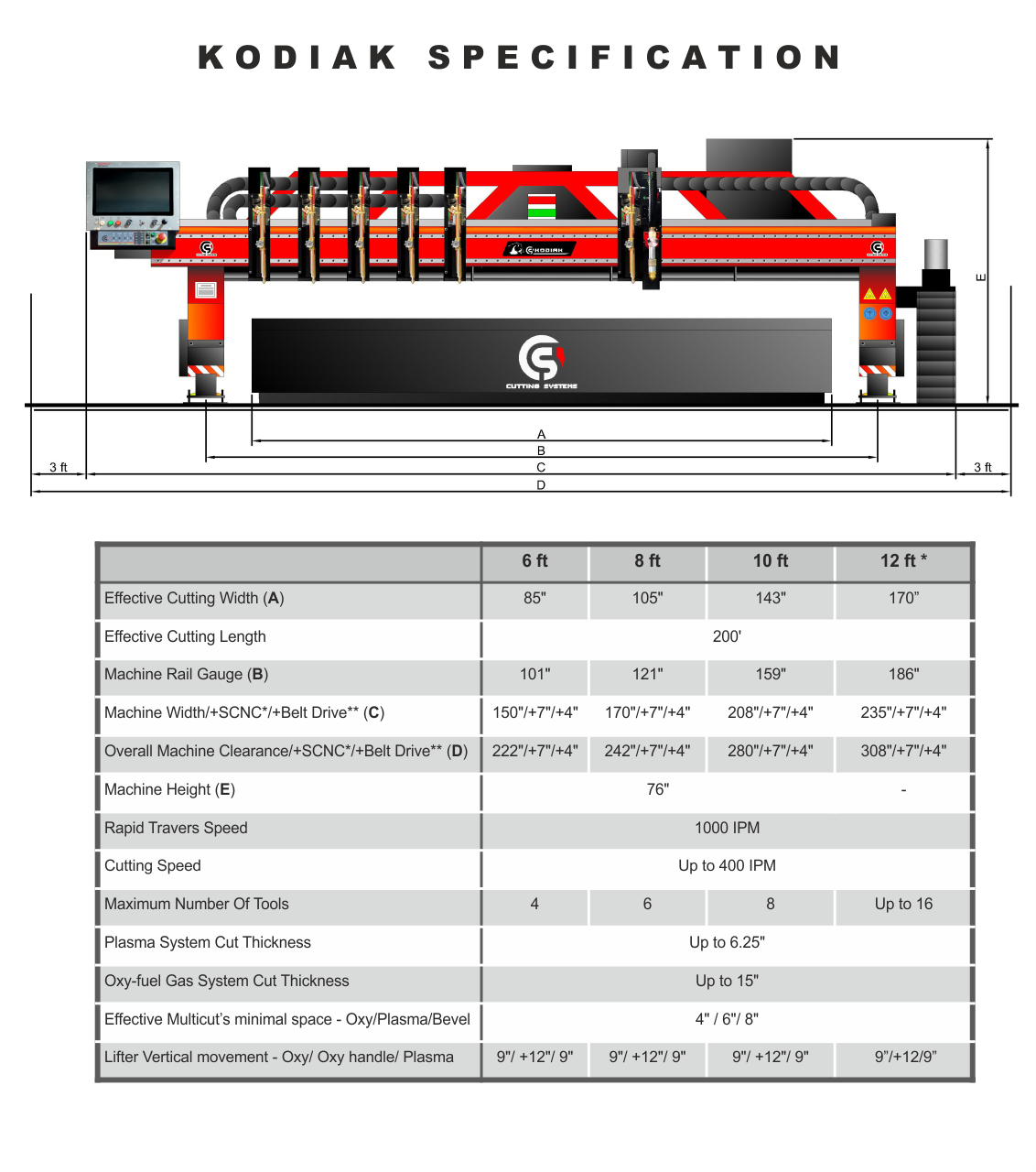

- Standard effective cutting widths: 6', 8', 10', 12' (Custom widths up to 30' effective cutting). Effective cutting lengths up to 250'

- The Kodiak can be fully customized to meet your unique application.

- The Kodiak is appropriate for the following industries: heavy equipment manufacturing, mining, automotive, construction, steel fabrication, steel service centers and more.

- Over 30 different plasma systems to choose from

- Multiple plasma stations are available

- Manual bevel cutting (Plasma & Oxyfuel)

- Full contour bevel cutting (Plasma only)

- Standard and Jumbo oxy-fuel torches

- Automatic oxy-fuel torch ignition

- Oxy-fuel torch spark shields

- Manual oxy-fuel bevel cutting

- Torch spacing band or bar

- Manual or automatic torch spacing

- Laser pointer for accurate plate alignment

- Water and downdraft cutting tables

- Dust collectors and fume extractors

- CNC CAD/CAM nesting software

- Custom bridge widths (Up to 30 feet wide)

- I-Beam rail systems available

- Preventative maintenance kits

- Oxy-fuel consumables