Dust Collection Hood & Dust Collector Air Port

Have a Question about Dust Collectors?

Ask a QuestionAIR-PORT FUME EXHAUST HOOD FEATURES

- Two-person install in under an hour

- Pre-installed ductwork in legs and cross beams

- Optional integrated Spark Trap available

- Two-legged design means a smaller footprint

- Concave fume extraction hood design contains smoke and fumes

- Dampers for easy air flow adjustment

- Designed for manual and robotic welding

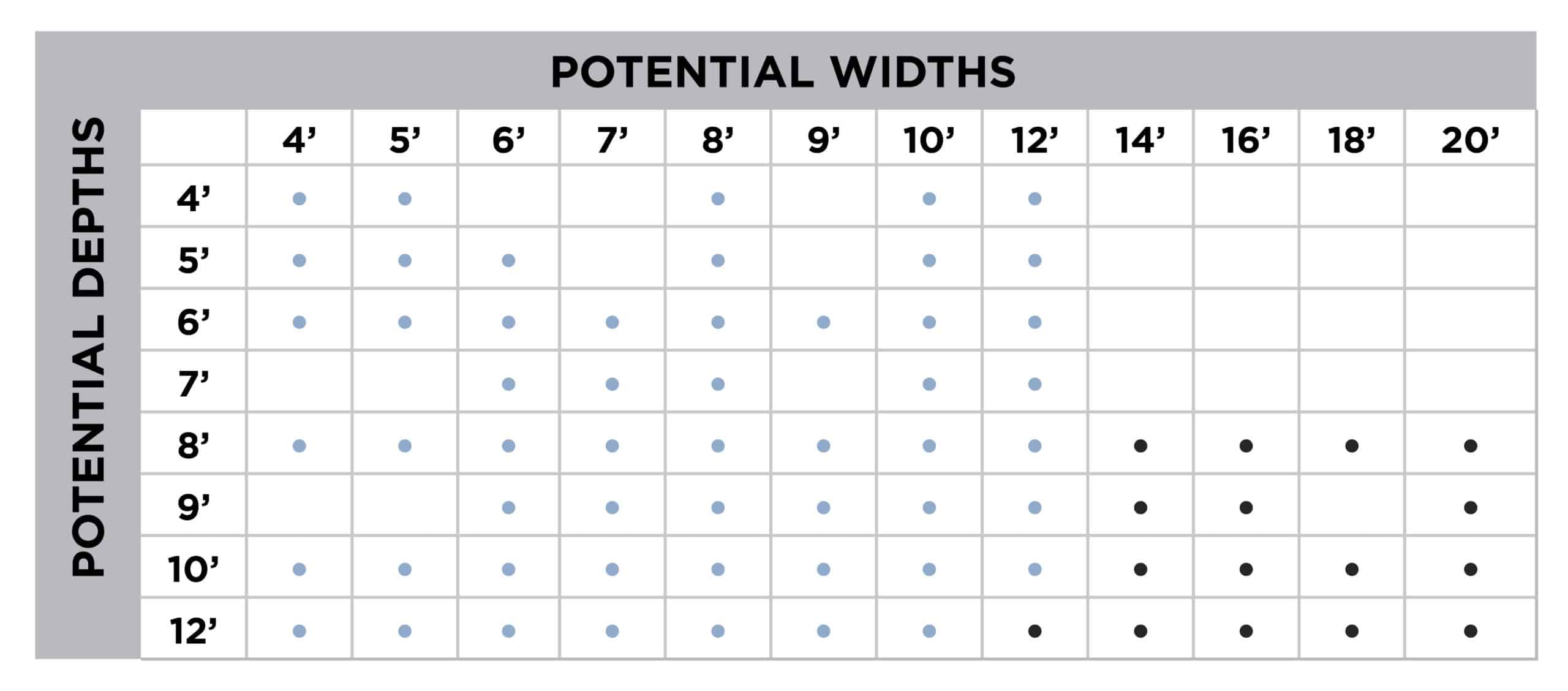

The Air-Port Fume Exhaust Hood is available in a variety of sizes. They begin at 4’ x 4’ and range all the way up to 12’ x 20’. Standard heights include 8, 9, and 10 feet. Taller hoods may be available. Note that ducted fume hoods marked with a darker dot may require ducting to both support legs.

Why should I choose the Air-Port Fume Exhaust Hood when there are cheaper alternatives on the market?

Alternative #1 – Other Fume Hoods

The Air-Port Fume Exhaust Hood was designed with the customer and mind, and offers benefits not available with other fume extraction hoods. While some of these welding fume hoods stand on four legs and also require ducting, the Air-Port is a ducted fume hood that incorporates the ducting into one or both of its two legs. This saves floor spaces, and makes it easier for a welder to navigate beneath the hood.

Alternative #3 – Fume Arms

Fume arms are a common solution for welding fume extraction systems, but aren’t always the most practical for those expected to use them. Fume arms can be dangerous for welders, especially those producing stainless steel welding fumes, as their use depends on the welder taking the time to move the arm to where they’re welding. For those welding all day, this can become an annoyance, and many welders can not be bothered.

A welding booth can be the perfect solution to this issue. As long as the hood is sized properly, welders should be able to do their job, moving freely beneath it while the hood removes dangerous weld fume from their breathing zone.

Alternative #2 – Weld Guns

A less common solution to weld fume is using weld guns. While these guns collect weld fume at the source, they may not reliably capture all the fume. Additionally, these guns are notoriously heavy and cumbersome for welders that may be using them all day long. This method may be best suited for robotic welding systems, but still may require some form of backup to capture all of the weld fume.

Alternative #4 – Downdraft Tables

Downdraft tables can be used to remove weld fume from a welders breathing area, but may come with restrictions. Downdraft tables may work best in ares where there are multiple types of fabrication occurring, such as welding and grinding. These table create a size restriction, as the work is limited to the space available on the table. Additionally, downdraft tables are not a viable solution for robotic welding systems.

The Air-Port Fume Exhaust Hood is available in a variety of sizes. They begin at 4’ x 4’ and range all the way up to 12’ x 20’. Standard heights include 8, 9, and 10 feet. Taller hoods may be available. Note that ducted fume hoods marked with a darker dot may require ducting to both support legs.

CRANE SLOT

A retractable opening in the extraction hood allows cranes to easily enter and place heavy equipment, like robotic spot welders, beneath the hood.

WELD CURTAIN

The Air-Port can include a blue welding strip curtain. It keeps both your welders and anyone walking through your facility safe from dangerous weld fume and smoke.

INTERNAL LIGHTING

Optional lighting in the hood provided increased visibility for welders and those servicing robotic welding systems.