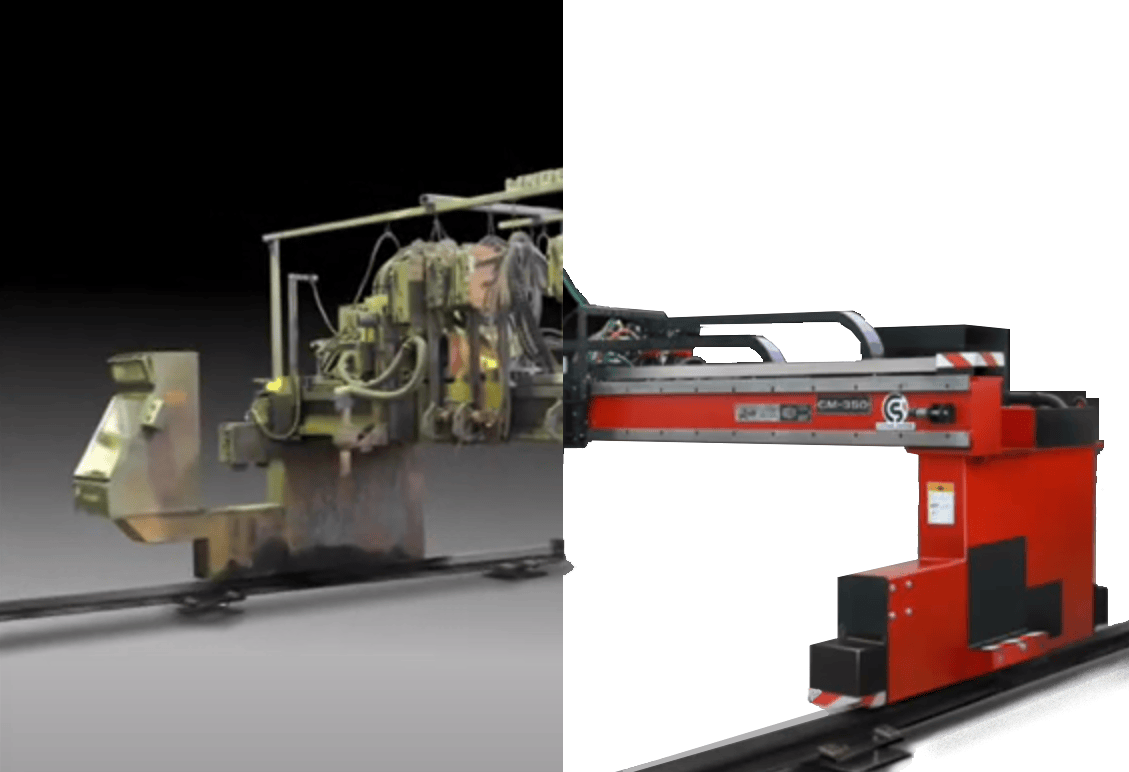

Is your old burning table showing its age? Maybe it’s slower than it used to be, or the cuts aren’t as sharp. Maybe you’re spending more time fixing it than actually using it. Before you start shopping for a brand-new system, consider this: retrofitting could be the smarter move.

At Cutting Systems, Inc. (CSI), we specialize in breathing new life into aging burning tables. Instead of replacing your entire setup, our controller and drive upgrades can transform your old machine into something that performs like new, often at a fraction of the cost. And sometimes, after seeing what’s possible with a retrofit, customers realize they want even more, leading them to invest in a completely new table.

Why Retrofit Instead of Replace?

Let’s be honest, buying a new burning table is a big investment. But what if you could get better speed, accuracy, and reliability without the hefty price tag? That’s where retrofitting comes in.

- Cost Savings: A full retrofit is often significantly cheaper than a new machine, especially if your table’s frame and structure are still solid.

- Familiarity: Your team already knows how to operate the existing table. A retrofit keeps the core system intact while upgrading the brains (controller) and muscle (drives).

- Sustainability: Instead of scrapping an old table, retrofitting extends its life, reducing waste and keeping usable equipment in service.

- Performance Boost: New controllers and drives mean faster processing, smoother motion, and cleaner cuts.

CSI’s Smart Upgrades for Burning Tables

1. Controller Upgrades: The Brain Behind the Brawn

The controller is the command center of your burning table. Older models might struggle with modern CAD/CAM files or lack the processing power for intricate cuts.

CSI offers high-performance CNC controllers that bring your table into the digital age. These upgrades support:

- Faster file processing: No more waiting for complex designs to load.

- Improved motion control: Smother acceleration and deceleration mean cleaner cuts with less dross.

- Compatibility with modern software: Work with the latest nesting and design programs without compatibility headaches.

2. Drive and Motor Upgrades: Power When You Need It

Old servo drives and motors wear out over time, leading to sluggish performance, missed steps, or even breakdowns. CSI’s high-torque servo systems eliminate these issues by:

- Increasing cutting speed: Faster axis movement means more parts per hour.

- Reducing backlash: Planetary gearboxes and precision ball screws keep motion tight and accurate.

- Improving reliability: New motors and drives mean fewer unplanned stops for repairs.

3. Torch Height Control & Automation Add-Ons

Manual torch height adjustment is time-consuming and inconsistent. CSI’s automatic height control systems ensure the torch stays at the perfect distance from the material, even on uneven surfaces. This means:

- Better cut quality: No more warped edges or uneven bevels.

- Longer consumable life: Proper standoff distance reduces wear on nozzles and electrodes.

- Hands-off operation: Let the machine do the fine-tuning while your team focuses on production.

When Does a Retrofit Turn Into a New Table Purchase?

Sometimes, retrofitting opens the door to bigger possibilities. Maybe your old table’s frame can’t handle the speed of the new drives. Or perhaps you see how much more you could do with a modern high-definition plasma system and decide it’s time for a full upgrade.

That’s the beauty of working with CSI; we don’t just sell machines, we help you find the best solution for your shop. Whether it’s a retrofit or a new table, our goal is to get you cutting better, faster, and with less downtime.

Ready to Give Your Burning Table a Second Life?

If your old table is holding you back, don’t rush to replace it, upgrade it instead. CSI’s retrofit solutions can make your machine feel brand new, and who knows? You might just fall in love with cutting all over again.

Contact Cutting Systems, Inc. today to discuss how we can modernize your burning table and keep your shop competitive.